Copper drawn bars are good electrical conductors and are appreciated for their flexibility, strength and endurance. In addition to the electrical panels cabling, Copper Bus bars are used in other electrical equipment for distribution or transmission of electricity, realisation of bus ducts and electric power supply lines of electrical field.

Thickness of 4 -5-10 mm - Length 1750 and 4200 mm

| Code | Reference | Code | Reference | Weight

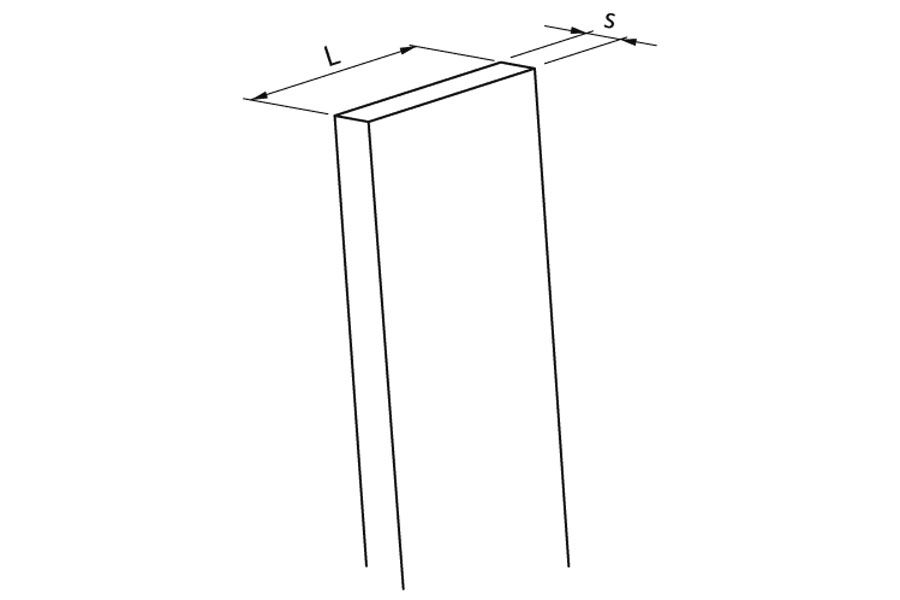

Kg/m | L

mm | s

mm |

|---|

| Lenght 1750 mm - Packing: 2 | Lenght 4200 mm - Packing: 1 |

| PRP2990 | PRP 12x4x1750 | PRP0990 | PRP 12X4 | 0,43 | 12 | 4 |

| PRP2000 | PRP 20x5x1750 | PRP1000 | PRP 20x5 | 0,89 | 20 | 5 |

| PRP2005 | PRP 25x5x1750 | PRP1005 | PRP 25x5 | 1,11 | 25 | 5 |

| PRP2010 | PRP 30x5x1750 | PRP1010 | PRP 30x5 | 1,33 | 30 | 5 |

| PRP2015 | PRP 40x5x1750 | PRP1015 | PRP 40x5 | 1,78 | 40 | 5 |

| PRP2020 | PRP 50x5x1750 | PRP1020 | PRP 50x5 | 2,23 | 50 | 5 |

| PRP2025 | PRP 60x5x1750 | PRP1025 | PRP 60x5 | 2,67 | 60 | 5 |

| PRP2030 | PRP 80x5x1750 | PRP1030 | PRP 80x5 | 3,56 | 80 | 5 |

| PRP2035 | PRP 100x5x1750 | PRP1035 | PRP 100x5 | 4,45 | 100 | 5 |

| PRP2040 | PRP 125x5x1750 | PRP1040 | PRP 125x5 | 5,56 | 125 | 5 |

| PRP2045 | PRP 30x10x1750 | PRP1045 | PRP 30x10 | 2,67 | 30 | 10 |

| PRP2050 | PRP 40x10x1750 | PRP1050 | PRP 40x10 | 3,56 | 40 | 10 |

| PRP2055 | PRP 50x10x1750 | PRP1055 | PRP 50x10 | 4,45 | 50 | 10 |

| PRP2060 | PRP 60x10x1750 | PRP1060 | PRP 60x10 | 5,34 | 60 | 10 |

| PRP2065 | PRP 80x10x1750 | PRP1065 | PRP 80x10 | 7,12 | 80 | 10 |

| PRP2070 | PRP 100x10x1750 | PRP1070 | PRP 100x10 | 8,90 | 100 | 10 |

| PRP2075 | PRP 120x10x1750 | PRP1075 | PRP 120x10 | 10,70 | 120 | 10 |

| | PRP1080 | PRP 160x10 | 14,25 | 160 | 10 |

| | PRP1085 | PRP 200x10 | 17,80 | 200 | 10 |

Copper bars - ampacity table

Ampacity table threaded copper bars based on the ΔT temperature increase as per standard DIN 43671.

Reference room temperature 35°C

| Dimensions | Sect. mm² | T 30° C | T 50° C |

|---|

| Numero di barre in parallelo | I | II | III | II II | I | II | III | II II |

| 12 x 4 | 48 | 160 | | | | 212 | | | |

| 12 x 5 | 60 | 183 | 334 | 460 | 514 | 241 | 440 | 607 | 679 |

| 15 x 5 | 75 | 218 | 405 | 567 | 635 | 289 | 537 | 751 | 841 |

| 20 x 5 | 100 | 274 | 500 | 690 | 772 | 363 | 663 | 914 | 1023 |

| 25 x 5 | 125 | 327 | 586 | 795 | 890 | 433 | 776 | 1053 | 1179 |

| 30 x 5 | 150 | 379 | 672 | 896 | 1003 | 502 | 890 | 1187 | 1329 |

| 32 x 5 | 160 | 400 | 695 | 931 | 1043 | 530 | 920 | 1234 | 1382 |

| 40 x 5 | 200 | 482 | 836 | 1090 | 1220 | 639 | 1108 | 1444 | 1617 |

| 50 x 5 | 250 | 583 | 994 | 1260 | 1411 | 772 | 1317 | 1670 | 1870 |

| 60 x 5 | 300 | 688 | 1150 | 1440 | 1613 | 912 | 1524 | 1908 | 2137 |

| 63 x 5 | 315 | 718 | 1197 | 1494 | 1673 | 951 | 1586 | 1980 | 2217 |

| 80 x 5 | 400 | 885 | 1450 | 1750 | 1960 | 1173 | 1921 | 2319 | 2597 |

| 100 x 5 | 500 | 1080 | 1730 | 2050 | 2296 | 1431 | 2292 | 2716 | 3042 |

| 125 x 5 | 625 | 1300 | 2022 | 2381 | 2666 | 1723 | 2679 | 3155 | 3532 |

| 20 x 10 | 200 | 427 | 734 | 959 | | 564 | 970 | 1269 | |

| 30 x 10 | 300 | 573 | 986 | 1289 | | 756 | 1300 | 1701 | |

| 40 x 10 | 400 | 715 | 1230 | 1609 | | 944 | 1624 | 2124 | |

| 50 x 10 | 500 | 852 | 1510 | 2040 | | 1129 | 2001 | 2703 | |

| 60 x 10 | 600 | 985 | 1720 | 2300 | | 1305 | 2279 | 3048 | |

| 80 x 10 | 800 | 1240 | 2110 | 2790 | | 1643 | 2796 | 3697 | |

| 100 x 10 | 1000 | 1490 | 2480 | 3260 | | 1974 | 3286 | 4320 | |

| 120 x 10 | 1200 | 1740 | 2860 | 3740 | | 2306 | 3790 | 4956 | |

| 160 x 10 | 1600 | 2220 | 3590 | 4680 | | 2942 | 4757 | 6201 | |

| 200 x 10 | 2000 | 2690 | 4310 | 5610 | | 3564 | 5711 | 7433 | |

Example of solid copper bar choice

In = 800 A; T max. = 85 °C - Ta = 35 °C ΔT (See Table with ΔT = 50 °C); numbers of bars in parallel = 1.

Result

- Prepunched copper bars: 63x5 (In= 951)

- Solid Copper Bar: 40 x 10 mm (In = 944 A); 63 x 5 mm (In = 951 A)

- Solid alluminium bars: 50 x 10 (In = 874 A)